PelletMasters Pellet Mills, Hammer Mills, and Fine Grinders

Give us a call, we are here to help.

|

|

|

|

for Wood

|

for Feed and Fertilizer

|

for course material

|

for fine material

|

|

|

|

|

|

.

|

|

|

Products are intended for use with animal feed, fertilizer, and fuel production, but are not in compliance

with food grade for human consumption unless otherwise specified in the product description.

|

Buy a Pellet Mill and Hammer Mill together

and receive 10% off the cost of a Hammer Mill

and optional Cyclone Attachment!

|

|

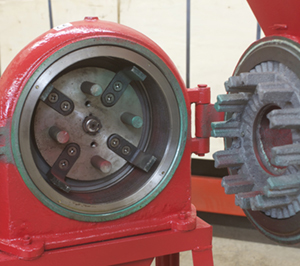

PelletMasters Pellet Mills for Wood

All PelletMasters Pellet Mills suitable for wood will also produce pellets from softer materials,

at a slightly lower production rate than a pellet mill designed for feed and fertilizer.

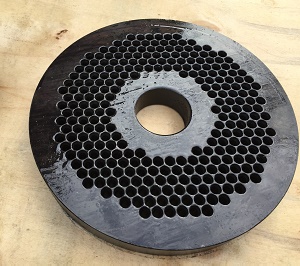

Pellet Mill Working Principles: Raw material is placed into the feeding hopper, which

leads to the pellet mill head, where the rollers and die are located. Material should not

exceed ½ to ¾ the height of the rollers. Material will be forced by the rollers through the

die creating heat and creating pellets. Pellets will exit the pellet mill through the discharge

port and will fall with gravity into your container. With the correct recipe of heat, moisture,

and force (pressure), you should be making perfect pellets.

A conservative estimate of production rate for our Pellet Mills with 6mm screens:

Electrically powered = ~20 pounds per horsepower per hour.

Gasoline, Diesel, and PTO powered = ~13 pounds per horsepower per hour.

Note: All new pellet mill dies must be conditioned before the first use.

Warning: Raw material should be no larger than the die hole size. If your material is larger

than the die hole size, material will need to pass through a Hammer Mill first.

PelletMasters Pellet Mills ship with a standard 6mm die.

Other die sizes available from 3mm to 8mm depending on the model.

Other die sizes are available upon request and can be special ordered.

All additional dies ship free with the purchase of a Pellet Mill.

Note: Actual mill color may vary.

|

220V 1ph Electric Pellet Mills for Wood

|

Note: 220V 1ph electricity is a standard in most residences.

Most electric ranges as well as electric clothes dryers utilize 220V 1ph power.

This is our own design and we are trying to gain information on interest for this machine.

We do not currently have inventory other than our prototype machine at this time. Coming Soon!

|

|

Die Size |

Power |

Price |

Availability: |

9"-2R |

10hp 220V |

$4,995 |

Prototype |

|

|

Potentially available in March/April of 2017.

Will be available with two roller option only.

|

|

Back to Menu

220V 3ph Electric Pellet Mills for Wood

|

Note: 220V 3ph electricity is usually found only in commercial and industrial buildings.

|

|

Die Size |

Power |

Price |

Availability: |

9"-2R |

10hp 220V |

$3,990 |

In Stock |

9"-3R |

15hp 220V |

$5,495 |

In Stock |

12"-2R |

20hp 220V |

$7,990 |

In Stock |

13"-3R |

30hp 220V |

$10,795 |

In Stock |

16"-3R |

40hp 220V |

$12,795 |

In Stock |

|

|

|

Back to Menu

|

|

Die Size |

Power |

Price |

Availability: |

8" |

7.5hp 220V |

$3,990 |

In Stock |

12" |

20hp 220V |

$7,990 |

By Request |

16" |

30hp 220V |

$11,490 |

By Request |

|

|

|

Back to Menu

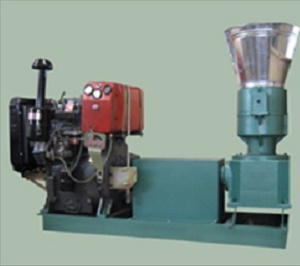

Diesel Powered Pellet Mills for Wood

|

Note: Due to shipping regulations, Acid for Battery shown is not included.

|

|

Die Size |

Power |

Price |

Availability: |

9"-2R |

15hp Electric Start |

$4,995 |

In Stock |

9"-3R |

22hp Electric Start |

$5,995 |

In Stock |

12"-2R |

35hp Electric Start |

$8,995 |

In Stock |

13"-3R |

55hp Electric Start |

$10,995 |

In Stock |

16"-3R |

55hp Electric Start |

$12,995 |

On Order |

|

|

Photos show 22hp and 55hp Diesel Engines.

|

|

Back to Menu

|

|

Die Size |

Power |

Price |

Availability: |

16" |

40hp Electric Start |

$12,990 |

By Request |

|

|

|

Back to Menu

|

|

Die Size |

Power |

Price |

Availability: |

8" |

15hp Electric Start |

$3,675 |

By Request |

10" |

22hp Electric Start |

$3,990 |

By Request |

12" |

32hp Electric Start |

$4,495 |

By Request |

12" |

50hp Electric Start |

$6,295 |

By Request |

14" |

55hp Electric Start |

$8,095 |

By Request |

16" |

55hp Electric Start |

$13,495 |

By Request |

|

|

|

Back to Menu

PTO Powered Pellet Mills for Wood

|

|

Model |

Recommended Power |

Price |

Availability: |

9"-2R |

15hp |

$2,995 |

In Stock |

9"-3R |

22hp |

$3,595 |

In Stock |

12"-2R |

35hp |

$5,495 |

By Request |

13"-3R |

45hp |

$5,995 |

In Stock |

16"-3R |

60hp |

$8,995 |

In Stock |

|

|

|

Back to Menu

|

|

Die Size |

Recommended Power |

Price |

Availability: |

8" |

15hp |

$2,390 |

In Stock |

10" |

22hp |

$2,990 |

By Request |

12" |

30hp |

$3,690 |

By Request |

14" |

45hp |

$4,690 |

By Request |

|

|

|

Back to Menu

PelletMasters Pellet Mills for Feed and Fertilizer

Pellet Masters offers pellet mills and hammer mills in sizes ranging from

small mills suited to home owners wishing to cut their feed and/or fuel bills to larger mills

suitable for the small scale production of pellets.

Pellet Mill Working Principles: Raw material is placed into the feeding hopper, which

leads to the pellet mill head, where the rollers and die are located. Material should not

exceed ½ to ¾ the height of the rollers. Material will be forced by the rollers through the

die creating heat and creating pellets. Pellets will exit the pellet mill through the discharge

port and will fall with gravity into your container. With the correct recipe of heat, moisture,

and force (pressure), you should be making perfect pellets.

A conservative estimate of production rate for our Pellet Mills with 6mm screens:

Electrically powered = ~20 pounds per horsepower per hour.

Gasoline, Diesel, and PTO powered = ~13 pounds per horsepower per hour.

Note: All new pellet mill dies must be conditioned before the first use.

Warning: Raw material should be no larger than the die hole size. If your material is larger

than the die hole size, material will need to pass through a Hammer Mill first.

PelletMasters Pellet Mills ship with a standard 6mm die.

Other die sizes available from 3mm to 6mm depending on the model.

Other die sizes are available upon request and can be special ordered.

All additional dies ship free with the purchase of a Pellet Mill.

PelletMasters Pellet Mills ship with a standard 6mm die.

Other die sizes available from 3mm to 8mm depending on the model.

Other die sizes are available upon request and can be special ordered.

All additional dies ship free with the purchase of a Pellet Mill.

Note: Actual mill color may vary.

|

220V 1ph Electric Pellet Mills

|

Note: 220V 1ph electricity is a standard in most residences.

Most electric ranges as well as electric clothes dryers utilize 220V 1ph power.

Note: The 5hp, 7.5hp, and 10hp single phase motors are locally sourced & American made motors.

|

|

Die Size |

Power |

Price |

Availability: |

5" |

3hp 220V |

$1,545 |

By Request |

5" |

4hp 220V |

$1,585 |

In Stock |

6" |

5hp 220V |

$2,990 |

In Stock |

6" |

7.5hp 220V |

$3,675 |

In Stock |

8" |

10hp 220V |

$3,685 |

In Stock |

|

|

|

Back to Menu

220V 3ph Electric Pellet Mills

|

Note: 220V 3ph electricity is usually found only in commercial and industrial buildings.

|

|

Die Size |

Power |

Price |

Availability: |

6" |

5.3hp 220V |

$1,700 |

In Stock |

6" |

7.5hp 220V |

$2,260 |

By Request |

8" |

10hp 220V |

$2,750 |

In Stock |

9" |

15 hp 220V |

$3,590 |

In Stock |

10" |

20 hp 220V |

$4,690 |

In Stock |

12" |

30 hp 220V |

$5,900 |

By Request |

16" |

40 hp 220V |

$7,990 |

In Stock |

|

|

|

Back to Menu

Gasoline Powered Pellet Mills

|

Note: Our supplier rates this engine as 7.5hp.

The engine is a clone of a Honda SX200 which Honda rates at 6.5hp.

|

|

Die Size |

Power |

Price |

Availability: |

5" |

6.5hp Pull Start |

$1,785 |

By Request |

6" |

6.5hp Pull Start |

$1,885 |

By Request |

6" |

13hp Electric Start |

$2,185 |

In Stock |

|

|

|

Back to Menu

Diesel Powered Pellet Mills

|

|

Die Size |

Power |

Price |

Availability: |

5" |

8hp Crank Start |

$1,895 |

By Request |

5" |

8hp Electric Start |

$2,395 |

By Request |

6" |

8hp Crank Start |

$1,990 |

By Request |

6" |

8hp Electric Start |

$2,495 |

In Stock |

8" |

15hp Crank Start |

$2,785 |

By Request |

8" |

15hp Electric Start |

$3,990 |

In Stock |

9" |

22hp Crank Start |

$3,390 |

By Request |

9" |

22hp Electric Start |

$4,290 |

In Stock |

|

|

Photos show 22hp Diesel Engine.

|

|

Back to Menu

|

|

Die Size |

Power |

Price |

Availability: |

10" |

30hp Electric Start |

$6,585 |

By Request |

12" |

55hp Electric Start |

$7,690 |

By Request |

14" |

55hp Electric Start |

$8,590 |

By Request |

16" |

55hp Electric Start |

$9,790 |

By Request |

|

|

|

Back to Menu

PTO Powered Pellet Mills

|

|

Die Size |

Recommended Power |

Price |

Availability: |

6" |

8hp |

$1,474 |

By Request |

8" |

15hp |

$2,275 |

In Stock |

9" |

22hp |

$2,390 |

In Stock |

10" |

30hp |

$2,975 |

By Request |

12" |

45hp |

$3,890 |

By Request |

14" |

50hp |

$4,690 |

In Stock |

16" |

60hp |

$5,990 |

In Stock |

|

|

|

Back to Menu

Non-Powered Shaft Drive Pellet Mills

|

|

|

Die Size |

Power |

Price |

Availability: |

5" |

Shaft |

$1,285 |

In Stock |

6" |

Shaft |

$1,285 |

In Stock |

8" |

Shaft |

$2,265 |

In Stock |

9" |

Shaft |

$2,485 |

By Request |

10" |

Shaft |

$2,965 |

By Request |

12" |

Shaft |

$4,465 |

By Request |

14" |

Shaft |

$5,965 |

By Request |

16" |

Shaft |

$6,565 |

By Request |

|

|

|

Back to Menu

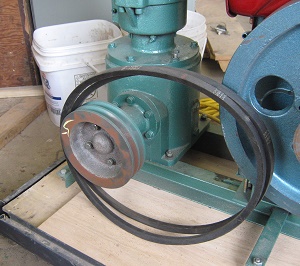

Non-Powered Pulley Drive Pellet Mills

|

|

|

Die Size |

Power |

Price |

Availability: |

5" |

Pulley |

$1,285 |

In Stock |

6" |

Pulley |

$1,285 |

In Stock |

8" |

Pulley |

$2,265 |

In Stock |

9" |

Pulley |

$2,785 |

In Stock |

|

|

These machines use qty. 2 V-Belt size B.

|

|

Back to Menu

PelletMasters Large Pellet Mills

Please contact David at Pellet Masters for more information regarding

these Pellet Mills. Phone: 715-726-3100

Large Pellet Mills

|

|

Die Size |

Power |

Price |

Availability: |

22" |

120hp Electric |

Call for Price |

By Request |

|

|

|

|

|

Back to Menu

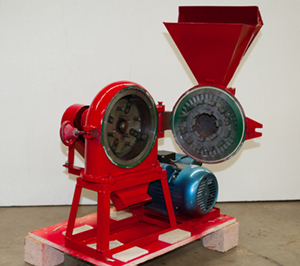

PelletMasters Fine Grinders

PelletMasters offers a line of grinders to reduce your materials to a smaller particle size that

our hammer mills are capable of. We offer grinders in varying sizes that are capable

of attaining particle sizes ranging from .4mm to 2mm.

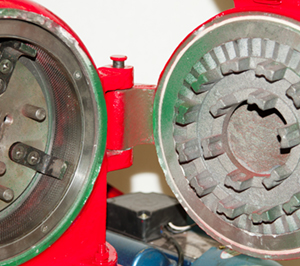

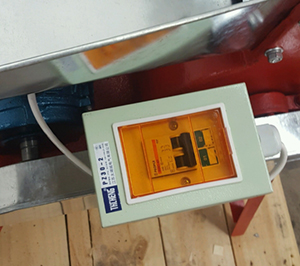

Grinder Working Principles: Raw material is placed into the feeding hopper, which leads to the

grinder chamber where the material enters the side and is beaten and crushed (ground) by high

speed rotating pins on one side and stationary pins on the other side. Under centrifugal force the

material is processed quickly due to continuous squeezing, crushing, and beating, by the grinder pins.

Under rotor centrifugal force and gravity, crushed material and air is discharged through the holes

in the 360 degree screen while those that cannot get through will repeat the process until they are

small enough to pass through the screen and out the discharge outlet where a dust bag should be

used to collect it.

Production rate for our Grinders varies greatly with the different screen sizes.

Warning: Raw material size entering the Grinder depends on type of material.

PelletMasters Fine Grinders ship with a standard 1.2mm screen.

Other screen sizes available from .4mm to 2mm depending on the model.

Additional screens are $34.00. All additional screens ship free with the purchase of a Hammer Mill.

Note: Actual mill color may vary.

|

220V 1phase Electric Grinder

|

Note: 220V 1ph electricity is a standard in most residences.

Most electric ranges as well as electric clothes dryers utilize 220V 1ph power.

|

|

|

Power |

Screen Dia. |

Price |

Availability: |

3hp 220V |

190mm |

$1,095 |

In Stock |

4hp 220V |

230mm |

$1,475 |

In Stock |

|

|

Back to Menu

Gasoline Fine Grinder

|

|

Power |

Screen Dia. |

Price |

Availability: |

6.5 hp Gasoline |

230mm |

$1,475 |

In Stock |

|

|

|

Back to Menu

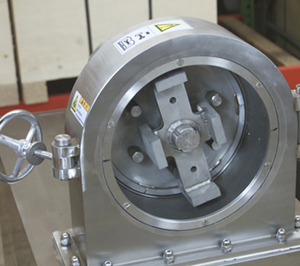

Stainless Steel Grinder

|

Stainless Steel Fine Grinders ship with a standard 100 mesh screen.

Other screen sizes available from 120 mesh to 10 mesh. Additional screens are $72.00.

All additional screens ship free with the purchase of a Stainless Steel Fine Grinder.

Note: This model is made with food grade 304 stainless steel, but does not include compliance labels.

|

|

Power |

Screen Dia. |

Price |

Availability: |

7.5 hp Electric |

100 mesh |

$5,995 |

On Order |

|

|

|

Back to Menu

Stainless Steel Grinder with Cyclone and Rotary Valve

|

Stainless Steel Fine Grinders ship with a standard 100 mesh screen.

Other screen sizes available from 120 mesh to 10 mesh. Additional screens are $72.00.

All additional screens ship free with the purchase of a Stainless Steel Fine Grinder.

Note: This model is made with food grade 304 stainless steel, but does not include compliance labels.

|

|

Power |

Screen Dia. |

Price |

Availability: |

7.5 hp Electric |

100 mesh |

T.B.D. |

By Request |

|

|

|

Back to Menu

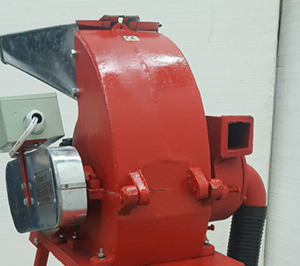

PelletMasters Hammer Mills

PelletMasters offers a wide range of hammer mills from small, perfect for the hobby farmer,

to larger models suitable for mid-sized industrial operations.

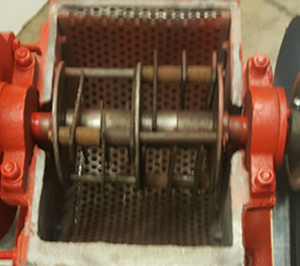

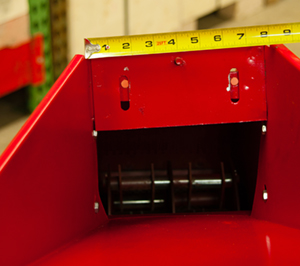

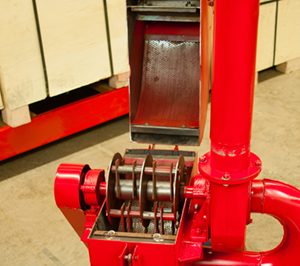

Hammer Mill Working Principles: Raw material is placed into the feeding hopper, which leads to the

hammer chamber where the material enters from the top and is beaten and crushed (hammered)

by high speed rotating blades. Under centrifugal force the material is processed quickly due to

continuous squeezing, crushing, and beating, by the hammer mill blades. Under rotor centrifugal

force, fan suction force, and gravity crushed material and air is discharged through the holes in

the 180 degree screen on the bottom while those that cannot get through will repeat the process

until they are small enough to pass through the screen into the lower body of the hammer mill.

Blower: After material passes through the screen into the lower body, fan suction from the blower

forces air and material out the discharge outlet (model 158) where a dust bag should be used to

collect it or upward and into the cyclone (all other models).

Cyclone Attachment: The material and air coming from the hammer mill blower enters the cyclone at the

top on the side. The material then falls in a circular motion through a downward vortex of the cyclone’s

outer chamber to the bottom where the material exits the cyclone. At the same time the clean air

flows through an upward vortex of the cyclone’s inner chamber to the top where it exits the cyclone.

A conservative estimate of production rate for our Hammer Mills with 6mm screens:

158 Hammer Mill = ~30 pounds (1/2 bushel) of shell corn per minute.

198 Hammer Mill = ~60 pounds (1 bushel) of shell corn per minute.

420 Hammer Mill = ~150 pounds (2 ½ bushels) of shell corn per minute.

Warning: Raw material size entering the Hammer Mill depends on type of material.

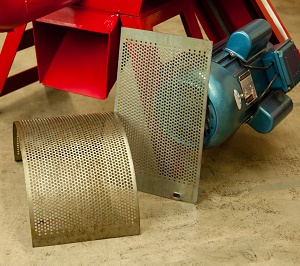

PelletMasters Hammer Mills ship with a standard 6mm screen.

Other screen sizes available from 2mm to 10mm depending on the model.

Additional screens are $28.00 for model 158, $38.00 for model 198, and $49.00 for model 420.

All additional screens ship free with the purchase of a Hammer Mill.

Note: Actual mill color may vary.

|

220V 1ph Electric Hammer Mills

|

Note: 220V 1ph electricity is a standard in most residences.

Most electric ranges as well as electric clothes dryers utilize 220V 1ph power.

|

|

|

Model |

Power |

Price |

Availability: |

158 |

3hp 220V 1ph. |

$1,395 |

In Stock |

|

|

Back to Menu

Shown with optional

Cyclone Attachment. Available for an additional $165.00.

|

|

|

Model |

Power |

Price |

Availability: |

198 |

4hp 220V 1ph. |

$1,695 |

In Stock |

|

|

|

Back to Menu

Shown with optional

Cyclone Attachment. Available for an additional $245.00.

|

Note: 10hp motor is a locally sourced American made motor.

|

|

|

Model |

Power |

Price |

Availability: |

420 |

10hp 220V 1ph. |

$4,390 |

In Stock |

|

|

|

Back to Menu

220V 3ph Electric Hammer Mills

|

Shown with optional

Cyclone Attachment. Available for an additional $165.00.

|

Note: 220V 3ph electricity is usually found only in commercial and industrial buildings.

|

|

|

Model |

Power |

Price |

Availability: |

198 |

5.3hp 220V 3ph. |

$1,695 |

In Stock |

|

|

|

Back to Menu

Shown with optional

Cyclone Attachment. Available for an additional $245.00.

Cyclone Attachment for model 500 available for an additional $345.00.

|

Note: Photos show model 420 Hammer Mill measurements and size.

|

|

|

Model |

Power |

Price |

Availability: |

420 |

10hp 220V 3ph. |

$2,990 |

By Request |

420 |

15hp 220V 3ph. |

$3,395 |

In Stock |

500 |

30hp 220V 3ph. |

$5,995 |

By Request |

|

|

Back to Menu

Gasoline Powered Hammer Mills

|

Shown with optional

Cyclone Attachment. Available for an additional $165.00.

|

Note: Our supplier rates this engine as 7.5hp,

This engine is a clone of a Honda SX200 which Honda rates at 6.5hp.

|

|

|

Model |

Power |

Price |

Availability: |

198 |

6.5hp Gasoline |

$1,695 |

In Stock |

|

|

|

Back to Menu

Diesel Powered Hammer Mills

|

Shown with optional

Cyclone Attachment. Available for an additional $245.00.

Cyclone Attachment for model 500 available for an additional $345.00.

|

Note: 22hp and 55hp Diesel motors are equipped with electric start.

Note: Photos show model 420 Hammer Mill measurements and size.

Note: Due to shipping regulations, Acid for Battery shown is not included.

|

|

|

Model |

Power |

Price |

Availability: |

420 |

22hp Diesel |

$3,590 |

In Stock |

500 |

55hp Diesel |

$8,295 |

By Request |

|

|

Photos show 22hp Diesel Engine.

|

|

Back to Menu

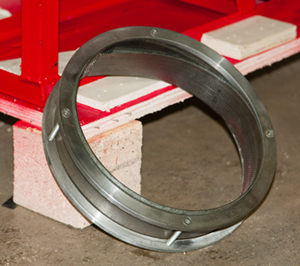

PelletMasters Spare Parts

PelletMasters offers a wide range of Spares and Replacement Parts

PelletMasters Pellet Mills and Hammer Mills ship with standard 6mm dies and screens.

Other die and screen sizes available from 2mm to 10mm depending on the model.

Additional die and screen costs very depending on the size and model of the mill.

All additional dies and screens ship free with the purchase of a Mill.

Spare and Replacement Parts

|

Call for costs and availability.

|

|

|

|

Back to Menu

Packaging and Delivery

Our machines are packaged securely to a strong plywood case with a pellet securely

fastened to the base for easy loading and unloading.

Industrial Machinery

These are industrial machines are internally wired up and ready to go, but they not wired up for

your specific power receptacle because there are many different options available. You will be able to

use whichever plug and receptacle you choose in accordance with the power required by the machine.

Warranty and Returns

We stand behind our products. If you ever have any problems, we are here to answer the phone.

We carry a large inventory of alternate and general maintenance replacement parts.

If for some reason you receive your machine and it isn't what you expected or you changed your mind,

leave it in the crate and send it back for a full refund less shipping costs.

Be Careful and Follow All Safety Guidelines!