|

PelletMasters Hammer Mills

Congratulations on your purchase of a PelletMasters Hammer Mill.

Please ensure all belts have the correct tension; tight, but not too tight.

They may loosen or tighten during shipping.

Double check the Hammer Mill cotter keys on the hammers are secured.

Please ensure all fasteners and zerks are tight; they may loosen during shipping.

Nothing leaves our warehouse damaged. We take special care in preparing our shipments to help avoid potential shipping damage.

Please inspect your crate thoroughly before signing the delivery receipt. If damage is found, have the driver note it on the delivery receipt.

|

|

|

|

|

Packaging and Delivery

Our machines are packaged securely to a strong plywood case with a pellet securely

fastened to the base for easy loading and unloading.

|

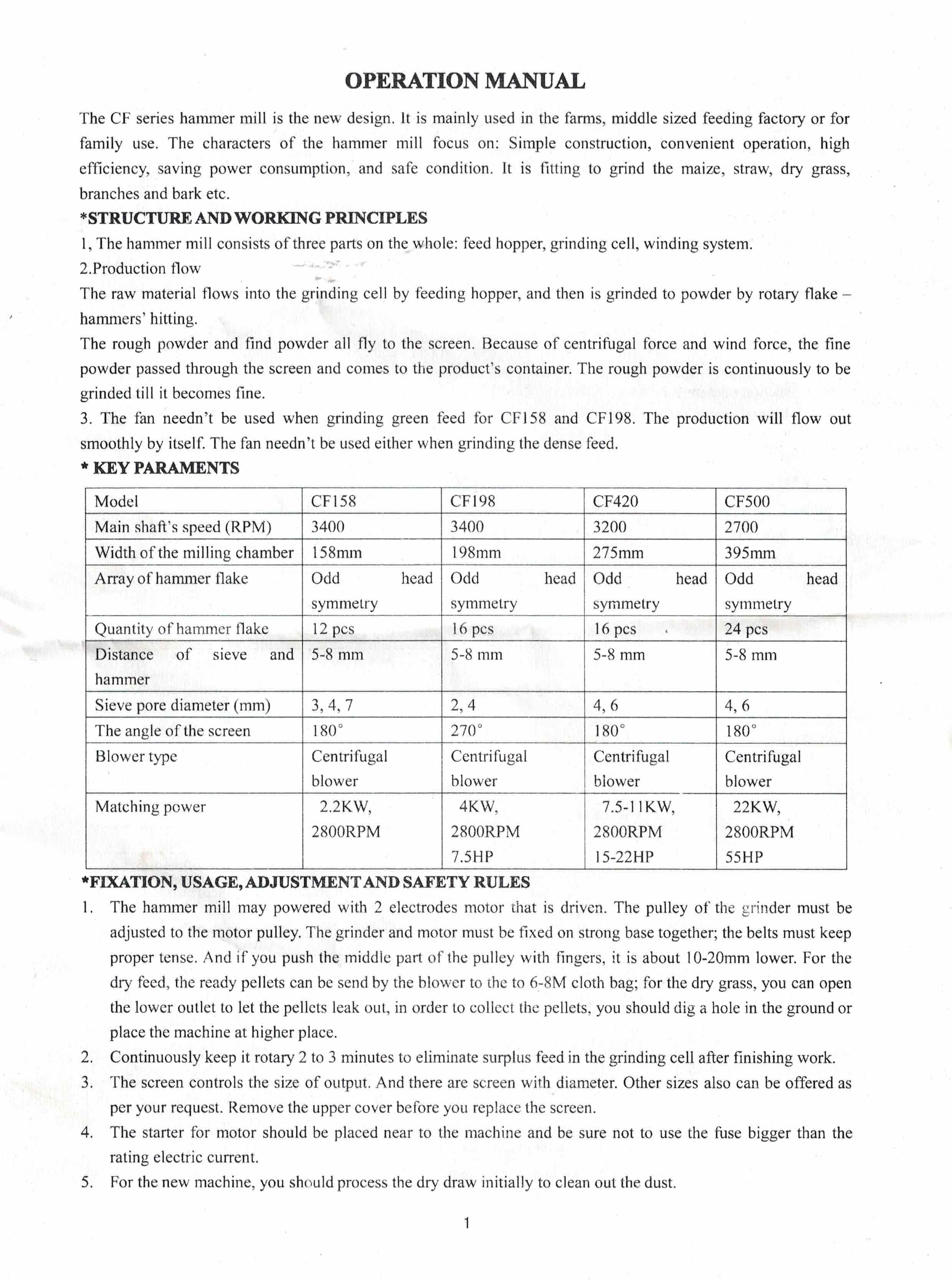

Industrial Machinery

These are industrial machines. They are internally wired up and ready to go, but are not wired up for

your specific power receptacle because of the many different options available. You will be able to

use whichever plug and receptacle you choose in accordance with the power required by the machine.

your specific power receptacle because of the many different options available. You will be able to

use whichever plug and receptacle you choose in accordance with the power required by the machine.

|

Warranty and Returns

We stand behind our products. If you ever have any problems, we are here to answer the phone.

We carry a large inventory of alternate and general maintenance replacement parts.

If for some reason you receive your machine and it isn't what you expected or you changed your mind,

leave it in the crate and send it back for a full refund less shipping costs both ways.

|

Be Careful and Follow All Safety Guidelines!

|

|

|

|

|

Pellet Masters in beautiful Chippewa Falls, Wisconsin.

We have an office and shop in downtown Chippewa and a warehouse a few miles away.

Chippewa Falls is also the home of the Leinenkugel Brewing Company and Cray Research Inc.

We have the largest in stock selection of flat die pellet mills in North America

with over 100 machines ready to ship from our warehouse in Chippewa Falls, Wisconsin.

|

|

|

|

|

|